Purpose-Built Shelters for Aggregate Quality & Consistency

Over the years at Varna Buildings, our team has continuously refined our storage solutions to meet the specific demands of key sectors. In the aggregates and bulk materials industry, where exposure to the elements can rapidly degrade material quality, the need for reliable, weather-resistant storage is critical. Our structures are designed to protect valuable materials in even the most unpredictable climates, ensuring longevity, compliance, and operational efficiency.

Protecting Aggregates Starts with SkyShield™

When bulk materials like ballast, Type 1 are left exposed to the elements, quality suffers and costs rise. SkyShield™ container canopies offer a modular solution designed specifically for aggregate yards. As seen in the image, we provided O’Connors with a tailored SkyShield™ system to protect their ballast stockpile — preventing rain from degrading material quality or causing separation. By shielding materials from weather and contamination, SkyShield™ helps operators reduce waste, maintain compliance, and protect profits year-round.

Uncovered Stockpiles Cost You Time and Money

Without protection, exposed stockpiles often require annual cycling or reprocessing — removing, drying, and restocking aggregate to restore quality. Water retention from rain can increase the weight of aggregates by 5–8%, meaning you’re often paying to transport water instead of usable material. This not only throws off batching accuracy but also inflates haulage and material costs. The rehandling process typically adds 10–15% extra labour and machine time, stretching workforce hours and increasing wear on plant. The compensation time, energy, and fuel — especially if re-drying is needed — can cost operators thousands per week on high-volume sites.

Protecting Aggregates Starts with SkyShield™

When bulk materials like ballast, Type 1 are left exposed to the elements, quality suffers and costs rise. SkyShield™ container canopies offer a modular solution designed specifically for aggregate yards. As seen in the image, we provided O’Connors with a tailored SkyShield™ system to protect their ballast stockpile — preventing rain from degrading material quality or causing separation. By shielding materials from weather and contamination, SkyShield™ helps operators reduce waste, maintain compliance, and protect profits year-round.

Uncovered Stockpiles Cost You Time and Money

Without protection, exposed stockpiles often require annual cycling or reprocessing — removing, drying, and restocking aggregate to restore quality. Water retention from rain can increase the weight of aggregates by 5–8%, meaning you’re often paying to transport water instead of usable material. This not only throws off batching accuracy but also inflates haulage and material costs. The rehandling process typically adds 10–15% extra labour and machine time, stretching workforce hours and increasing wear on plant. The compensation time, energy, and fuel — especially if re-drying is needed — can cost operators thousands per week on high-volume sites.

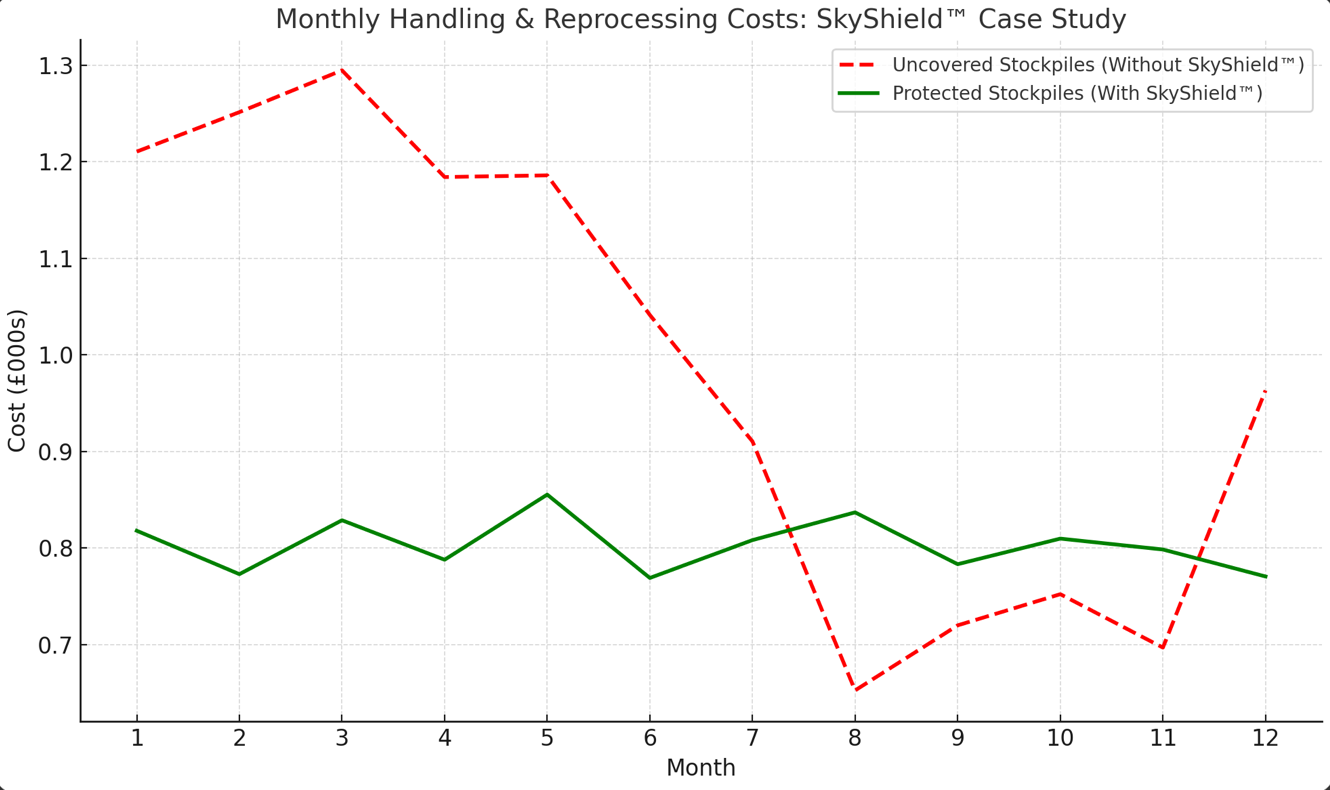

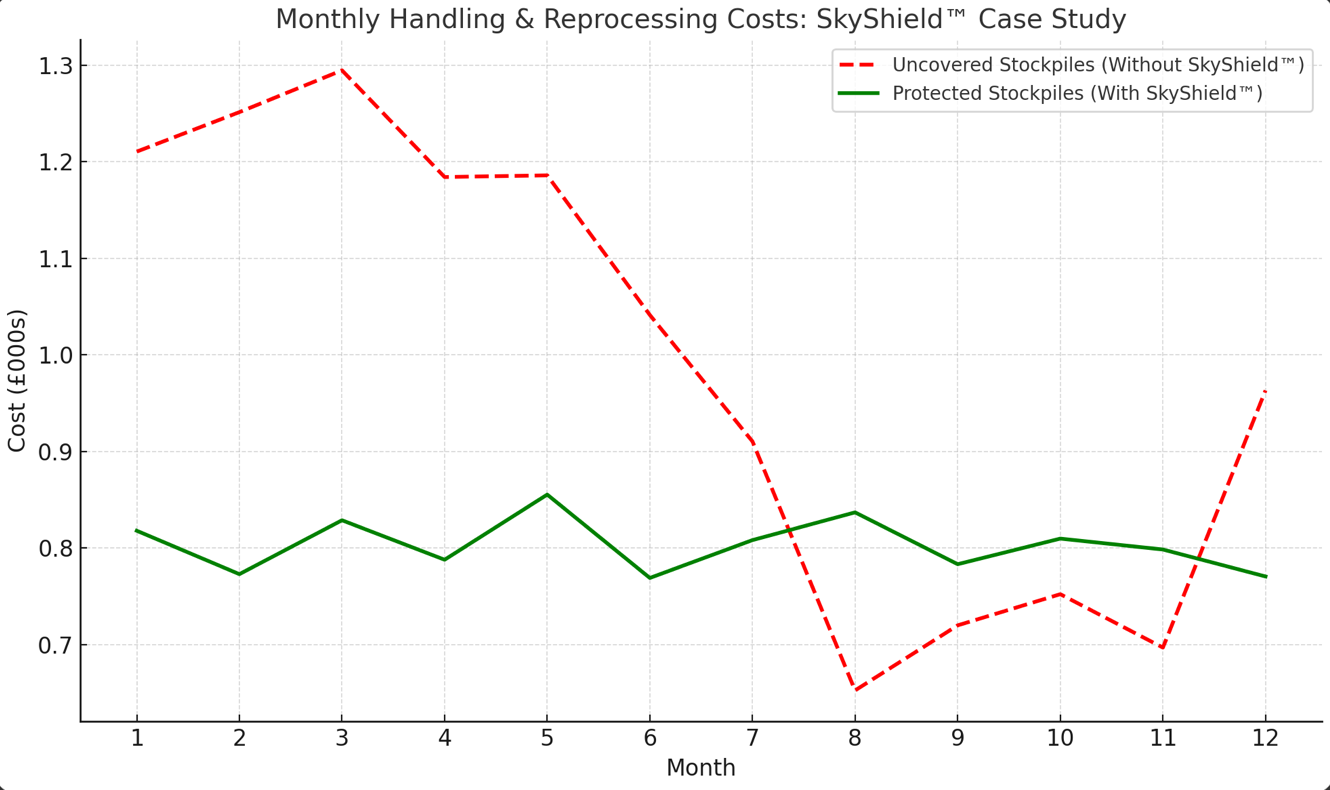

SkyShield™ Reduces Annual Handling Costs by Up to 30%

This case study compares the monthly reprocessing and handling costs of a high-output aggregate yard operating with and without SkyShield™ protection. Uncovered stockpiles experienced significant cost spikes due to rain-soaked materials, increased water weight, and frequent rehandling. In contrast, the SkyShield™-protected yard maintained consistent material quality, eliminating the need for drying, reshifting, or corrective batching. Over the course of a year, SkyShield™ delivered an estimated 25–30% reduction in material handling costs, while also improving compliance and reducing machine wear. For operators managing thousands of tonnes per month, the savings quickly scale into the tens of thousands.

SkyShield™ Reduces Annual Handling Costs by Up to 30%

This case study compares the monthly reprocessing and handling costs of a high-output aggregate yard operating with and without SkyShield™ protection. Uncovered stockpiles experienced significant cost spikes due to rain-soaked materials, increased water weight, and frequent rehandling. In contrast, the SkyShield™-protected yard maintained consistent material quality, eliminating the need for drying, reshifting, or corrective batching. Over the course of a year, SkyShield™ delivered an estimated 25–30% reduction in material handling costs, while also improving compliance and reducing machine wear. For operators managing thousands of tonnes per month, the savings quickly scale into the tens of thousands.

SkyShield™ Container Canopy – Aggregates Industry FAQ

How long does installation take?

Most SkyShield™ systems are installed within 2–5 working days from delivery, depending on site access and size. We pre-configure units off-site to reduce downtime during assembly.

Do SkyShield™ canopies require planning permission?

In most cases, no planning permission is needed. Our modular container-based design qualifies as temporary or semi-permanent infrastructure, making it ideal for fast-moving projects, rail depots, or short-term aggregate storage contracts.

Can SkyShield™ be relocated or expanded?

Absolutely. Our modular systems are fully relocatable, expandable, and reusable — ideal for evolving sites, short-term projects, or rented yards. New canopy bays can be added as your material volumes grow.

What materials are SkyShield™ canopies suitable for?

SkyShield™ canopies are engineered for storing all types of bulk construction materials, including Type 1, MOT, ballast, sand, recycled aggregates, and more. Our structures protect against rain, UV, and wind, helping prevent material degradation and cross-contamination.

How does weather exposure affect aggregate quality?

Leaving aggregates exposed to rain increases moisture content, which inflates transport weight, alters compaction, and throws off mixing ratios. In some cases, excessive water can cause fines to separate or wash away, lowering material quality.

Can SkyShield™ reduce costs associated with material rehandling?

Yes. By keeping materials dry and clean, SkyShield™ canopies reduce the need for annual stockpile cycling, manual reprocessing, and re-drying. Many clients report up to 30% annual savings in labour and machine time related to rehandling wet or contaminated materials.