Non-Insulated Steel Buildings

> Overview

Our Non‑Insulated Steel Buildings are permanent, commercial‑grade structures engineered for warehouses, workshops, logistics hubs and agricultural storage. Unlike temporary fabric shelters, these are rigid steel frame buildings with steel cladding, designed for longevity, low maintenance and fast installation.

Frames are fabricated in galvanised structural steel and supplied CE certified to EN 1090. Each building is designed to Eurocodes for wind and snow actions with project‑specific load calculations available for building control approval. The range below covers popular spans and eaves heights; lengths are modular and can be extended by bay.

Note: Dimensions shown are Width × Length × Eaves height. Metric equivalents are included in each section.

> Key Benefits (All Models)

- Permanent heavy‑duty structure – hot‑dip galvanised frame with steel roof/walls.

- Compliance‑ready – CE marked to EN 1090 with Eurocode design packs for approvals.

- Low lifetime cost – minimal maintenance, long service life vs. temporary structures.

- Modular bays – extend length or add openings without redesigning the whole building.

- Fast build – pre‑engineered components reduce onsite time and disruption.

> Options & Add‑Ons

- Roller shutters, sectional overhead doors, personnel doors.

- Roof‑lights and wall‑lights for daylighting; guttering and downpipes.

- Anti‑condensation roof liner; mesh ventilation; bird‑proofing details.

- Mezzanine platforms, internal partitions, racking interfaces.

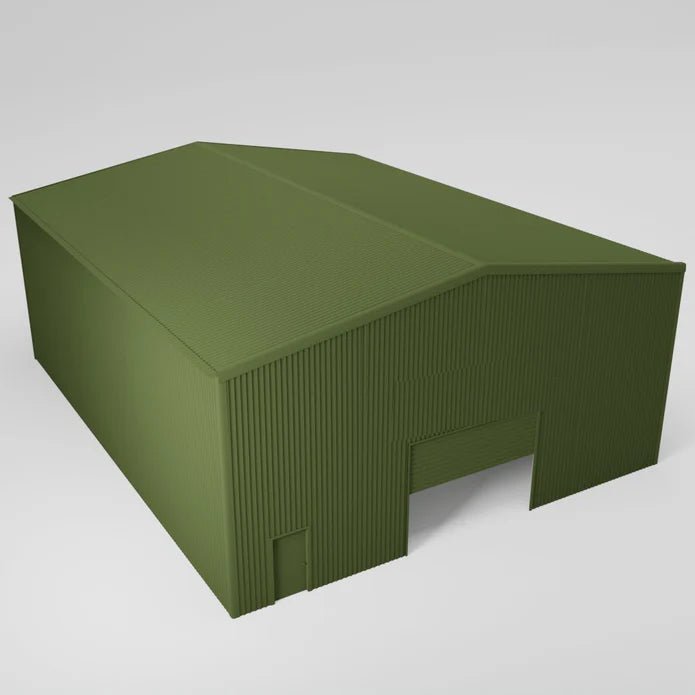

- Paint finishes and cladding colours to corporate palette.

> 50ft × 40ft × 21ft (15 × 12.2 × 6.4m)

Compact commercial unit suited to small logistics bays, farm workshops or contractor depots. 21ft (6.4m) eaves provides forklift and small HGV clearance.

| Frame | Galvanised structural steel, CE certified to EN 1090 |

|---|---|

| Cladding | Single‑skin steel roof & walls, anti‑condensation liner optional |

| Roof Pitch | ~10–15° (profiled steel) |

| Openings | Roller shutter up to 4.0m W × 4.5m H typical + personnel doors |

| Design Loads | To Eurocodes (site‑specific wind/snow); calcs pack available |

| Foundations | Anchor bolts to reinforced slab or strip/ground beams |

| Warranty | Frame 15 yrs · Cladding 10 yrs (typical) |

> Typical Uses

> 65ft × 40ft × 21ft (20 × 12.2 × 6.4m)

Adds extra length for racking aisles or vehicle queuing while keeping the compact 40ft span.

| Bays | Modular 5m–6m bays; extendable |

|---|---|

| Daylighting | Roof‑lights/wall‑lights optional to reduce lighting energy |

| Drainage | Galvanised gutters & downpipes |

| Fire Strategy | Non‑insulated steel; compartmentation & detection by client design |

> 100ft × 50ft × 24ft (30 × 15 × 7.3m)

A popular mid‑size warehouse/workshop with a wider 50ft span and 24ft eaves for tall racking or plant.

| Clearances | Approx. 7.3m eaves; ridge ~9–10m (pitch dependent) |

|---|---|

| Doors | Multiple roller shutters/sectional doors along long elevation |

| Mezzanine | Mezz floors & stair towers compatible |

| Loads | Eurocode wind/snow per postcode exposure category |

> 130ft × 50ft × 24ft (40 × 15 × 7.3m)

Extended length for higher throughput operations – ideal for production lines or long racking runs.

| Structure | Portal frame with braced bays; crane beams optional (by design) |

|---|---|

| Ventilation | Ridge vents, louvres, or mesh panels available |

| Lighting | Roof‑lights + LED high‑bay provision |

> 165ft × 50ft × 24ft (50 × 15 × 7.3m)

Large‑format warehouse providing significant linear storage or production capacity while retaining a 50ft span for efficient steel tonnage.

| Bays | Typical bay length 6m; customise to yard/site geometry |

|---|---|

| Corrosion | HDG finish as standard; paint topcoats optional for coastal/industrial zones |

| Warranty | Frame 15 yrs · Cladding 10 yrs (typical) |

> Typical Uses

> Installation, Foundations & Compliance

- Foundations – reinforced concrete slab or ground beams with cast‑in anchors.

- Programme – pre‑engineered kit; typical onsite assembly measured in weeks (size dependent).

- Design Pack – GA drawings, calcs, anchor plans, and O&M documentation included.

- Standards – CE marking to EN 1090; designed to Eurocodes for wind/snow actions.

- H&S – Erection by qualified teams under RAMS; CDM compliant.

> FAQs